Project details

Project:

Rothmühle AES GmbH (DE) – Planning of wet fermentation plant

Process area:

Case Studies

Charging material:

• 32,000 t/a

• Municipal organic waste and food waste

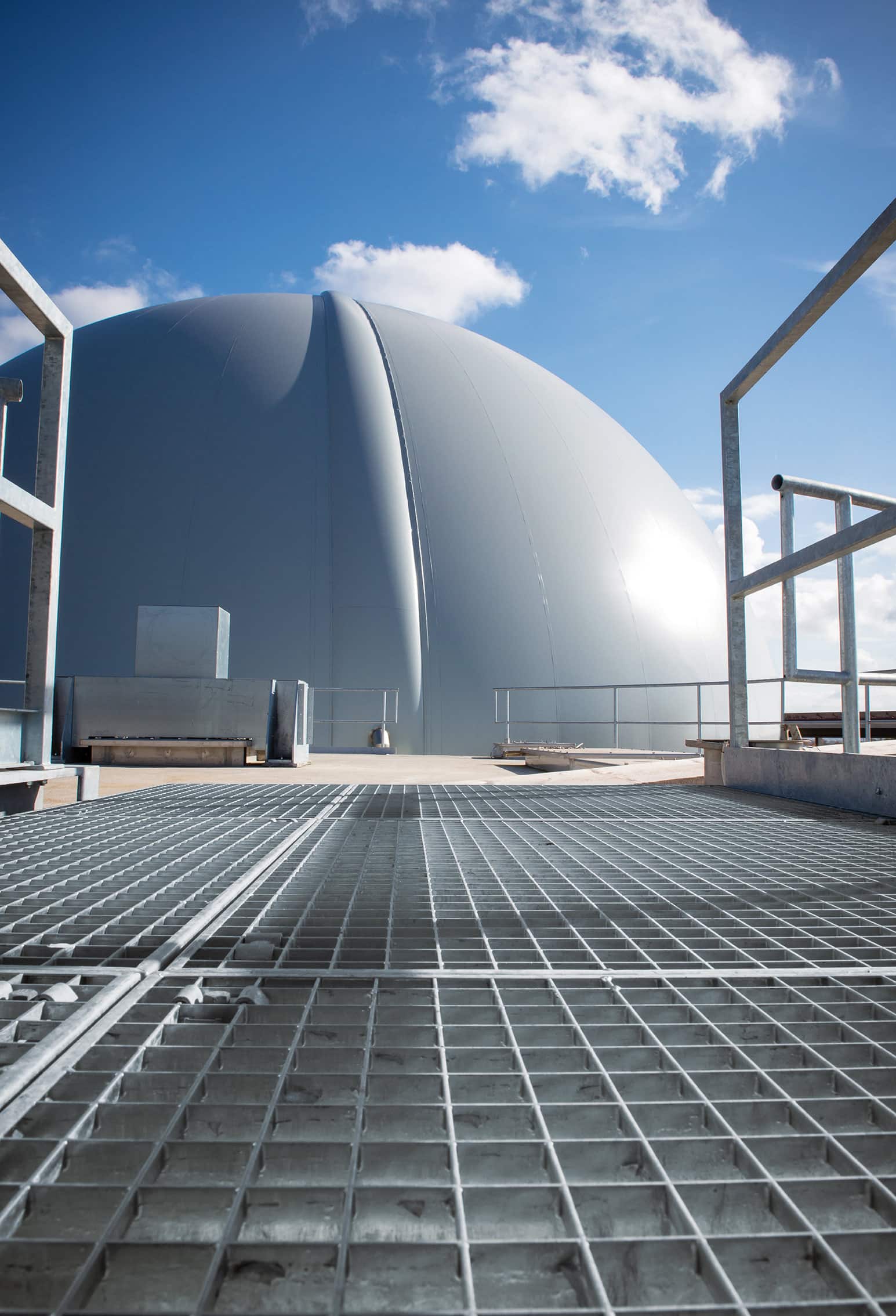

Planning of wet fermentation plant – Rothmühle biogas plant

The Rothmühle biogas plant(AES GmbH) was designed with the aim of efficiently and sustainably recycling organic waste from private households. In total, the plant processes around 25,000 tons of separately collected organic waste per year. The waste is separated into two fractions: Coarse fractions with a grain size of more than 100 mm are treated in a dry fermentation plant, while fine fractions with a grain size of less than 100 mm are recycled in a specially designed wet fermentation plant.

The biogas produced during fermentation from both plants is collected in a joint gas storage facility and then converted into electricity in several combined heat and power plants (CHP). This integrated system ensures maximum energy utilization of the gas obtained. Finsterwalder was entrusted with the planning, delivery and commissioning of the wet fermentation plant and its technical integration with the existing dry fermentation plant. Finsterwalder was also responsible for supervising the concrete construction, but did not act as the contractor itself.

Overview

Waste treatment processes

The procedure in detail

Receiving bunker

The first step in the process chain is the receiving bunker. With a volume of around 200 m³, it is designed for daily deliveries. The delivered waste is transferred from the bunker to the processing unit using a fully automated crane system. This automation not only ensures a continuous material flow, but also safe and efficient operation.

Separation of impurities

After the initial shredding using standard technology, impurities are separated. Here, coarse non-fermentable components such as plastics, metals or glass are removed. The solid impurities are pressed through two Finsterwalder BS20 BioSqueeze units to reduce the liquid content and then sent for composting. The pressed liquid substrate is fed to the hygienization unit to kill pathogenic germs and prepare the material for fermentation.

Hygienization with double-tube heat exchanger

In the hygienization unit – a double-tube heat exchanger – the substrate is heated to around 75 °C and sanitized. This is necessary to kill pathogens and meet the legal requirements for the treatment of organic waste. The sanitized material is then ready to enter the fermentation process.

Pumping technology

The pump technology used pump technology is designed for long-lasting continuous operation. The pumps are made of high-quality ST52 structural steel, while the scraper shaft is made of corrosion-resistant 1.4571 stainless steel. Even after four years of continuous operation, there is no sign of corrosion – neither on the shafts nor on the scraper bodies. This speaks for the high quality of the materials used and the well thought-out design of the components.

Continuous sediment discharge with patented bottom scraper

To ensure continuous operation of the fermenters, a Finsterwalder BR13 bottom scraper (1) is installed in each fermenter. This reliably conveys accumulated sediment into a sediment separator (2), where it is collected and then removed in regular cycles. Currently, around 8 tons of sediment are removed per day (3). Without this measure, the digesters would be unusable in less than a year due to sediment deposits.

Continuous light material discharge

Another technical highlight is the continuous light material skimmer (1) in each fermenter. This removes floating foreign matter such as plastic particles, which would otherwise form a floating blanket and hinder the fermentation process. The sorted out materials are removed from the fermentation residue in an external screening plant (2). (3) These are mainly fibrous materials and various plastics.

Energy generation and use

The wet fermentation plant produces an average of 250 m³ of biogas per hour. Together with the gas from the dry fermentation process – around 125 m³/h – this gas is stored in a 9000 m³ gas storage facility above the final storage facility. It is then converted into electricity in several CHP units directly on the plant site. During the construction of the wet fermentation plant, an additional 800 kWel of electrical power was installed. This contributes significantly to the energy self-sufficiency and economic efficiency of the plant.

Utilization of the fermentation product

The digestate produced during fermentation is collected in the final storage facility and used as a liquid fertilizer in agriculture during the growing season. All relevant quality criteria in accordance with the Fertilizer Ordinance are met. In this way, the plant not only contributes to energy production, but also to the return of valuable nutrients to the natural cycle.

Status June, 2024

Similar projects

Our technology offers individual solutions for all process areas in the field of biogas and anaerobic digestion of organic waste. We support our customers from the initial idea through to planning, implementation, commissioning and ongoing operation. Similar projects of our worldwide customers can be found here!

Digestion, Pasteurization, Pumps

Toronto ZooShare (CA) – Biogas plant

Charging material:

• 12,000 t/a

• Commercial and municipal food waste

Pasteurization, Pre-Treatment, Pumps, Top

Entsorgungsbetriebe Lübeck (DE) – Processing of food waste

Charging material:

• 5,000 t/a

• Food waste and municipal biowaste

Digestion, Pre-Treatment

Buchholz biogas plant (LU – treatment plant

Charging material:

• 7,550 t/a

• agricultural substrates

• Food waste and organic waste