Project details

Project:

Biowaste treatment Asdokshof – Pumptechnology

Process area:

Case Studies

Charging material:

unknown

Short description of the project

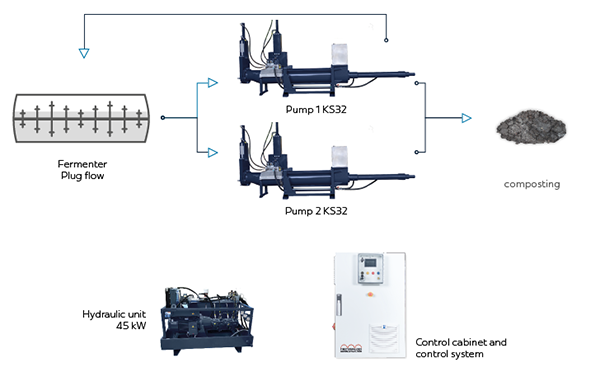

The biowaste treatment plant at the Asdonkshof waste and energy center in Kamp-Lintfort processes and treats biowaste for the district of Wesel. Approximately 28,500 tons of biowaste are processed and composted each year. The project was implemented as a general contractor by STRABAG Umwelttechnik GmbH. Finsterwalder Umwelttechnik, in turn, was commissioned to supply and install the pump technology for circulating and transferring the fermentation product from the fermenter to the composting facility. The pump capacity is adjustable between 30 m³/h at 6-8 bar delivery pressure. The two pumps are located outside, on the fermenter discharge side.

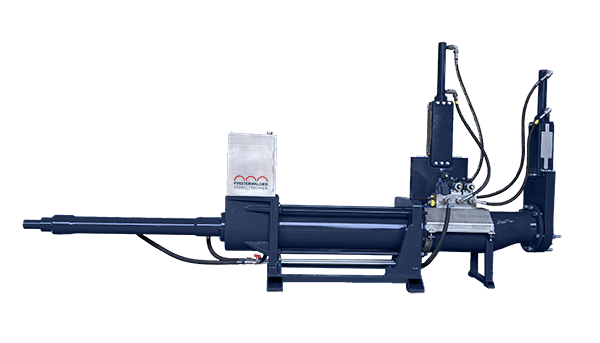

Integrated FINSTERWALDER technology

- 2x Gate valve pump KS32

- 1 x Hydraulikaggrega

- 1 x control unit

Services

- Delivery

- Construction

- Assembly

- Commissioning

- Maintenance

Waste treatment processes

Procedure in detail

Similar projects

Our technology offers individual solutions for all process areas in the field of biogas and anaerobic digestion of organic waste. We support our customers from the initial idea through to planning, implementation, commissioning and ongoing operation. Similar projects of our worldwide customers can be found here!

Digestion, Pasteurization, Pre-Treatment, Pumps

Bioenergie Kaiserwinkel (AT) – Biogas plant

Charging material:

• 5,000 t/a

• Leftovers from the catering trade

• Municipal waste

Digestion, Pre-Treatment

Bioenergy Schlitters (AT) – Waste pre-treatment and sediment discharge

Charging material:

• 10,000 t/a

• Commercial food waste

• Municipal waste

Pumps

Anröchte (DE) – Pump system with high solids content

Charging material:

• Digestate from dry fermentation