The all-rounder

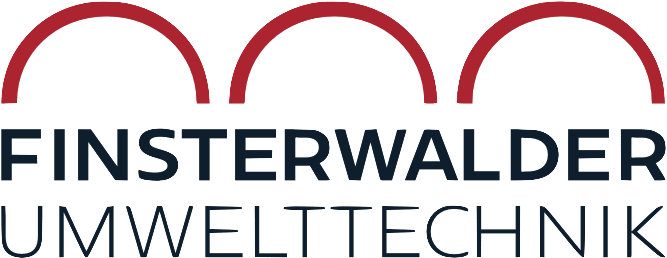

The KS23 slide valve pump is based on the large KV20 ball valve pump but, like the KP10 slide valve pump, has slide valves instead of ball valves. This makes it possible to convey substrates with isolated very large particles without the particles or fibers sticking or depositing.

Web visualization

Like every other machine from Finsterwalder Umwelttechnik, the KS23 gate valve pump has a touch panel on the control cabinet and web visualization. The machine can be easily controlled and settings can be made via the web HMI using any internet-enabled device. The process can also be monitored via this interface to ensure process reliability.

Technical data of the KS23 slider pump

- Suction side connection: DN200

- Connection on pressure side: DN200

- Flow rate (1 valve): 8.8 m³/h

- Flow rate (2 valves): 17.6 m³/h

- Delivery pressure: 12 bar

- Substrate temperature: 95 °C

- Parts in contact with media are acid-resistant

- Weight (1 or 2 valves): approx. 720 kg / 1,280 kg

- Ball passage: 200 mm

- Control cabinet and hydraulic unit included

Hydraulic power unit

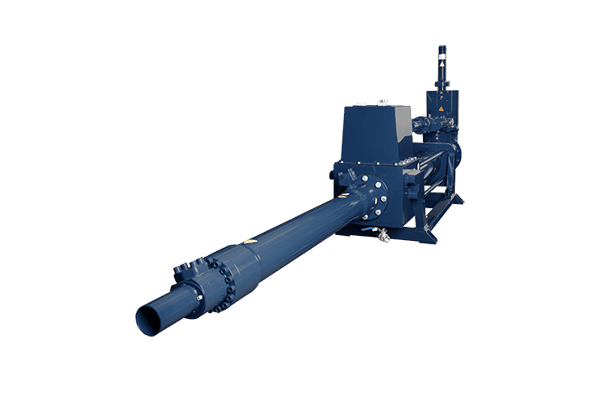

The hydraulic power unit drives the KV20 ball valve pump and the KS23 gate valve pump and can also actuate other valves in the system. It has a 600-liter oil tank, a WHG oil pan and consists of three oil circuits.

Similar products

Individual requirements also call for specific solutions. Our product range offers applications for a wide variety of process areas and can be adapted to your requirements. Find out more about the products we have developed and tested in our own plant.