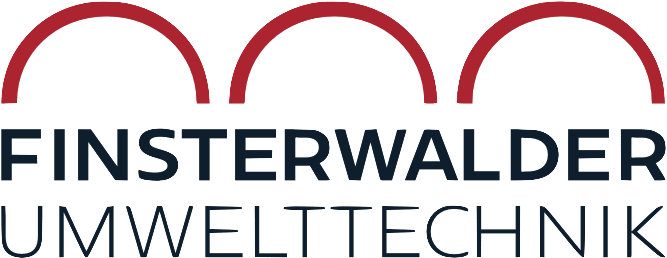

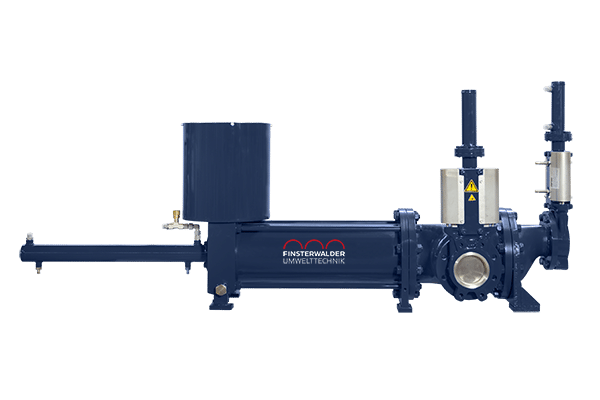

The little powerhouse – the KP10 piston pump

The KP10 piston pump is designed for the toughest and most wear-intensive applications. It is used when hot slurries or highly abrasive materials such as sand, stones, glass and metal splinters need to be pumped. The pumping process takes place by alternately opening the valves. As the hydraulically driven delivery cylinder moves forwards and backwards, the substrate is sucked into the pump through the inlet valve and pushed out through the outlet valve. This small powerhouse is ideal for sludges produced during the recovery and recycling of organic materials after pre-treatment, e.g. separated organic materials as well as biosolids and various other substrates and sludges. In addition to the pump, the scope of delivery includes a hydraulic unit and a control cabinet. The piston pump KP10 is available in the version as:

Non-return valve pump

- Closed system

- Variable slurries

- Ball passage up to 40 mm

and as

Slide valve pump

- Diffuser up to 80 mm

- Hydraulically driven gate valves DN100 PN10/16

Web visualization

Like every other machine from Finsterwalder Umwelttechnik, the small KP10 gate valve pump has a touch panel on the control cabinet and web visualization. The machine can be easily controlled and settings can be made via the web HMI using any internet-enabled device. This interface can also be used to monitor the pumping process, ensuring process reliability.

Technical data piston pump KP10

- Connection on the suction side: DN100

- Connection on the discharge side: DN100

- Flow rate: 5.2 m³/h

- Fluid/semifluid material, typical dry matter content 7-25%

- Delivery pressure: 8 bar

- Power requirement 5.5 kWel

- Substrate temperature: 95 °C

- Dimensions (LXW) 2,100 x 610 mm

- Special feature: completely sealed housing of the non-return valve

Hydraulic power unit

- 70 l oil tank made of aluminum and stainless steel

- Including temperature and level sensor

- Accumulator for smooth-running pistons

Economic efficiency

- Low wear part costs

- Low operating costs

- Also conveys large particles

- Virtually no downtime and high availability

Our pumps are used in the process areas of treatment and hygienization. They can also be used flexibly in other areas of application.

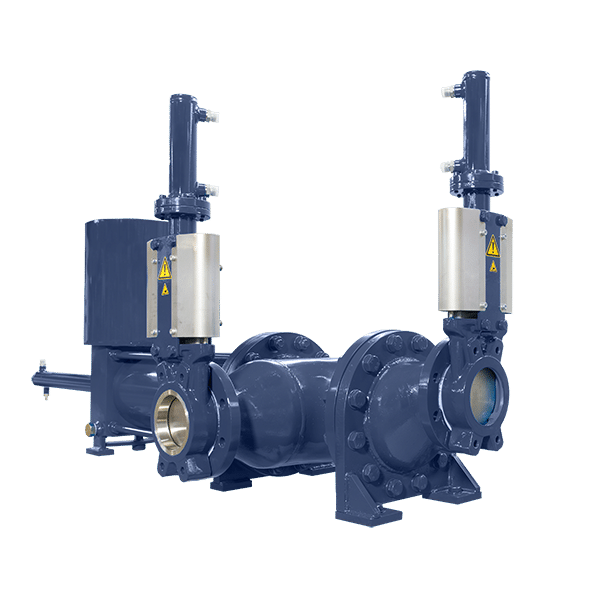

Similar products

Individual requirements also call for specific solutions. Our product range offers applications for a wide variety of process areas and can be adapted to your requirements. Find out more about the products we have developed and tested in our own plant.