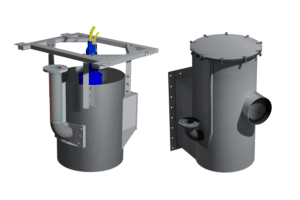

Patented FINSTERWALDER lightweight skimmer system –

Continuously remove and separate floating contaminants from the digester!

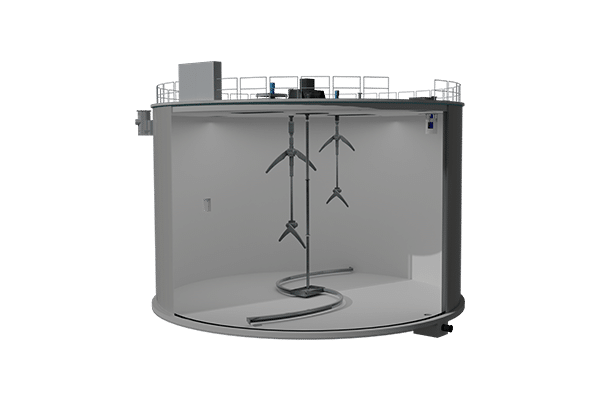

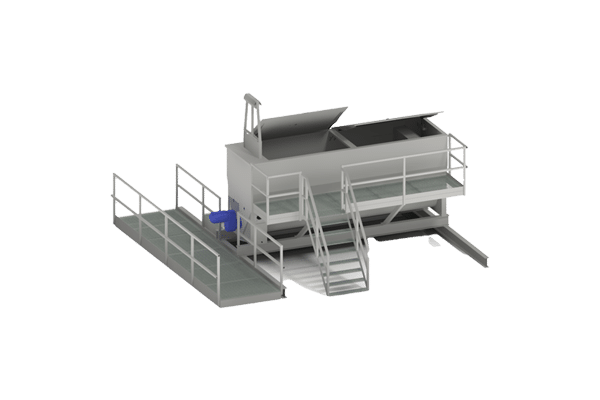

The light material skimmer system is used for the continuous discharge of floating materials from a fermenter/tank. The system consists of the patented skimmer and a standard screw separator.

Technical data

- Skimming of light materials (films, fibrous material, etc.) from the liquid surface

- Prevention of floating ceilings

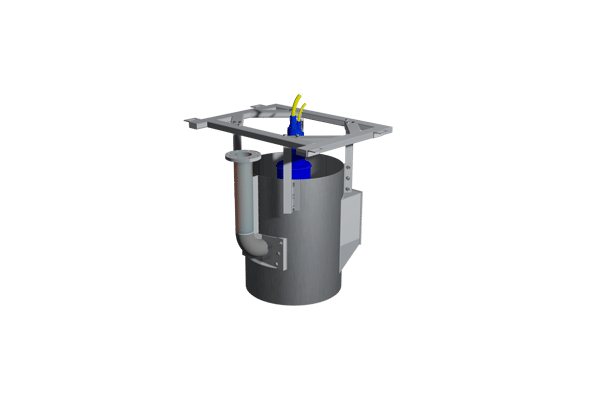

- Installation from above (LS01) or installation from the side (LS02)

- Gas-tight in every operating state due to its design

Technical data for the LS01 lightweight skimmer

- Installation situation – installation of digester ceiling

- Installation dimensions – opening 1100 x 1200 mm

- Weight (empty) – 170 kg

- Pressure connection – DN 100 / PN 16

- Connected load – 7 kW, 50 Hz; 380 – 420 V

- Ex zones – II2G EEx d ib IIB T4

Technical data for the LS02 lightweight skimmer

- Installation situation – side mounting

- Installation dimensions – cut-out 370 x 530 mm

- Weight (empty) – 360 kg

- Pressure connection – DN 100 / PN 16

- Connected load – 7 kW, 50 Hz; 380 – 420 V

- Ex zones – II2G EEx d ib IIB T4

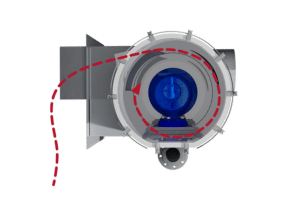

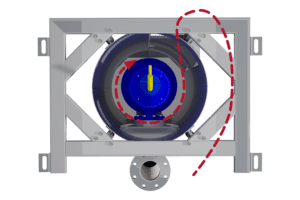

Functional principle of the lightoff skimmer

Lateral mounting

Mongage from above

VIDEO Skimmer in operation: Media library

Similar products

Individual requirements also call for specific solutions. Our product range offers applications for a wide variety of process areas and can be adapted to your requirements. Find out more about the products we have developed and tested in our own plant.