Automated process control for biogas plants with the bicarbonate analyzer

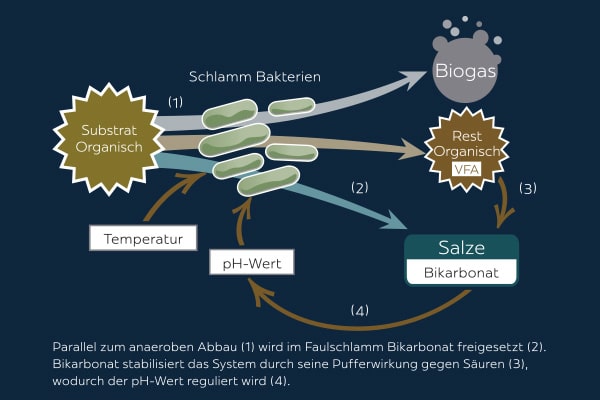

For efficient biogas production, digested sludge bacteria require a pH value in the range of around 6.5 to 8. Stabilization of the pH value in this range is predominantly (> 85 %) is achieved by the large quantities of bicarbonate (= buffer substance) released during anaerobic decomposition. Process disturbances regularly lead to increased concentrations of free fatty acids (FFA) or to decreasing bicarbonate contents, as the acids consume bicarbonate. However, the buffering effect of the bicarbonate means that the pH value is hardly reduced at first. Only if the disturbance lasts for a long time and the supply of bicarbonate is largely exhausted does a rapid drop in the pH value occur and subsequently a reduction or, in extreme cases, a failure of biogas production.

Advantages of process control with the bicarbonate analyzer

Advantages of process control with the bicarbonate analyzer

- Fully automatic monitoring of the bicarbonate content with the Bicarbonate Analyzer Process Monitor allows process faults to be detected much earlier than with pH monitoring alone. There is more time to avert economic losses.

- The high data density of the automatic measurement enables a close temporal assignment to changed operating conditions. This makes it much easier to identify the causes of process faults, which is often difficult.

- The automated measurement enables the biology to be monitored remotely and independently of people.

- BA42 measurement technology therefore increases the overall availability of biogas plants and thus their economic success.

Find out more about biology in the Fermeter

Similar products

Individual requirements also call for specific solutions. Our product range offers applications for a wide variety of process areas and can be adapted to your requirements. Find out more about the products we have developed and tested in our own plant.