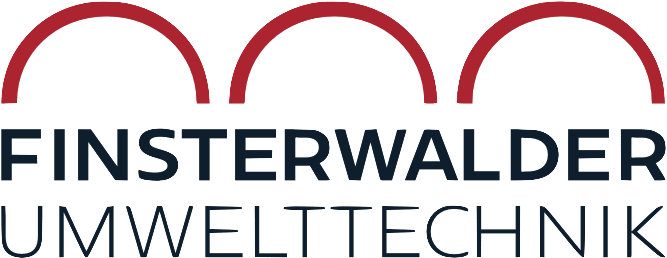

The robust way to pump

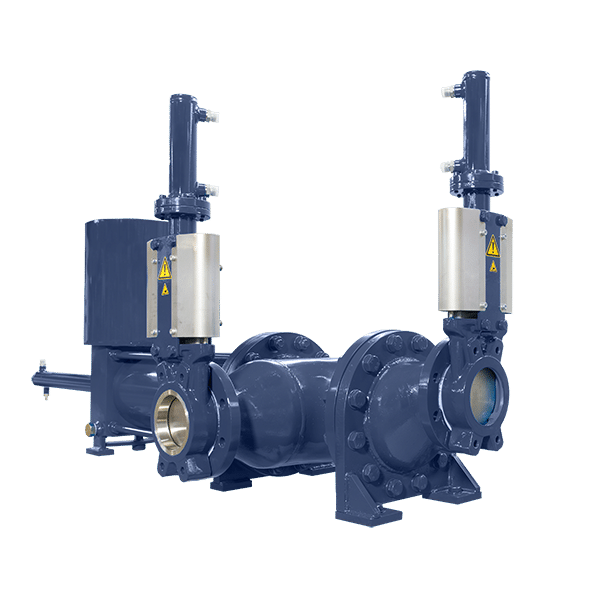

Finsterwalder hydraulically operated KV20 ball valve pumps, suitable for all types of free-flowing and largely homogeneous slurries, are extremely low-wear and insensitive to abrasion. Various drive modules are available, which are selected according to customer specifications.

The low-wear alternative

Ball valve pumps are characterized by a very simple design and are therefore less susceptible to faults. This applies in particular to media containing sand, as ball valve pumps do not contain any rotating parts. The KV20 is hydraulically driven and available with one or two ball valves, depending on the required flow rate.

Main features of the KV20 ball valve pump

- No rotating parts, i.e. an extremely robust and low-wear pump that is resistant to hard particles such as metal, bone and glass

- Max. Particle size up to 20 mm

- Flow rate up to 35 m³/h

- Pressures up to 40 bar

Options

Single ball valve – high-pressure option

Slower, even pumping processes, e.g. for feeding the FINSTERWALDER double-tube heat exchanger

Double ball valve – High flow rate

at medium pressure Fast, high-volume delivery for applications such as feeding fermenters or loading pre-treated food waste sludge into trucks.

Web visualization

Like every other machine from Finsterwalder Umwelttechnik, the KV20 ball valve pump has a touch panel on the control cabinet and a web visualization. The machine can be easily controlled and settings can be made via the web HMI using any internet-enabled device. The process can also be monitored via this interface, which ensures process reliability.

Technical data ball valve pump KV20

- Suction side connection: DN150

- Connection on pressure side: DN150

- Flow rate (1 valve): 9.4 m³/h

- Flow rate (2 valves): 18.8 m³/h

- Delivery pressure: 29 bar (up to 40 bar possible on customer request)

- Substrate temperature: 95 °C

- Particle size: max. 20 mm

- Parts in contact with media are acid-resistant

- Virtually pulsation-free

- Weight (1 or 2 valves): approx. 870 kg / 1,540 kg

- Control cabinet and hydraulic unit included

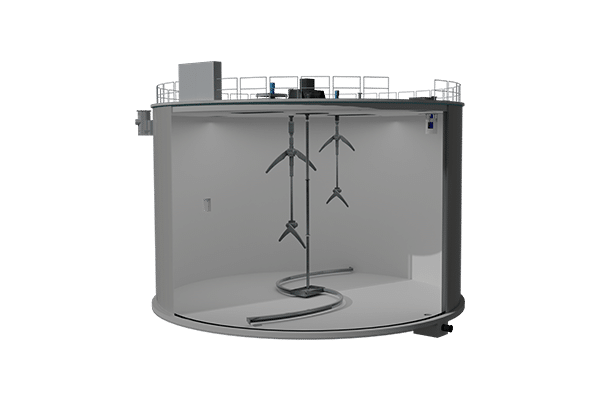

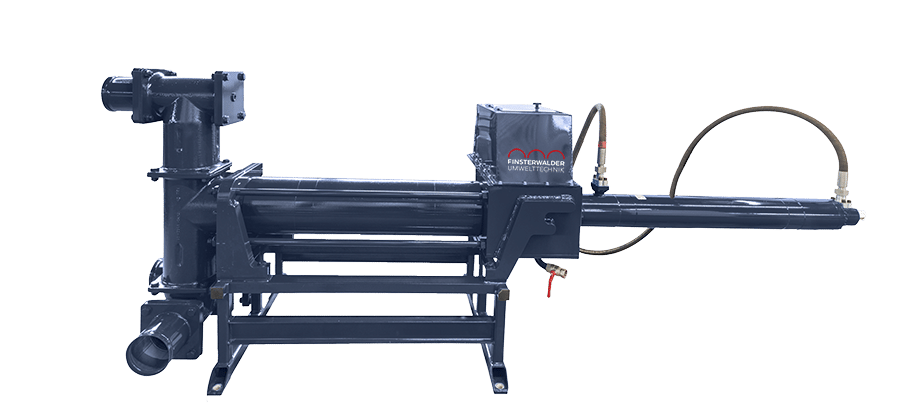

Hydraulic power unit

Hydraulic power unit

The hydraulic power unit drives the KV20 ball valve pump and the KS23 slide valve pump and can also actuate other valves in the system. It has a 600-liter oil tank, a WHG oil pan and consists of three oil circuits.

Similar products

Individual requirements also call for specific solutions. Our product range offers applications for a wide variety of process areas and can be adapted to your requirements. Find out more about the products we have developed and tested in our own plant.