Efficient recycling of organic waste

FINSTERWALDER APPLICATIONS

FINSTERWALDER APPLICATIONS

TECHNOLOGY AREAS OF APPLICATION

TECHNOLOGY AREAS OF APPLICATION

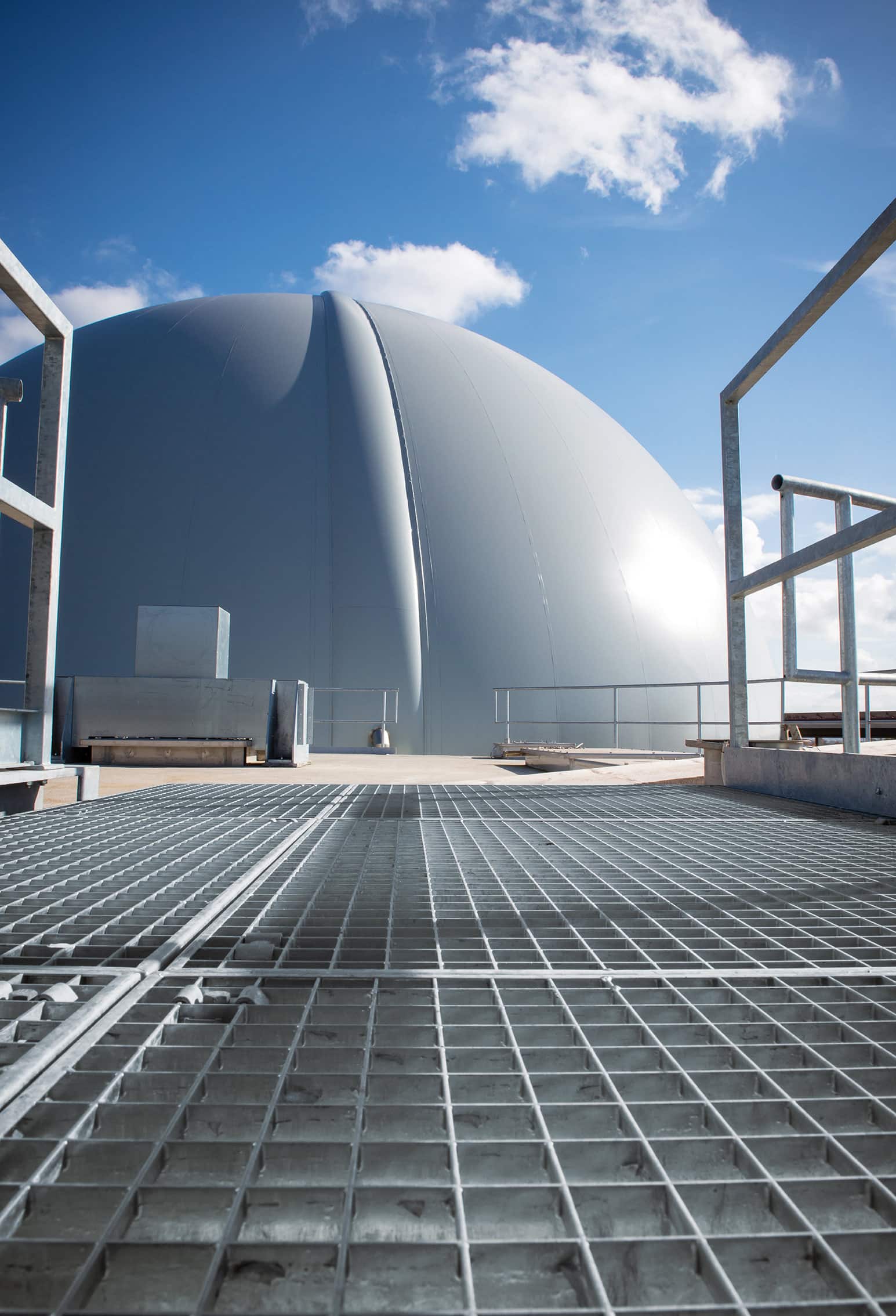

We utilize the potential of organic waste in our biogas technology division. There, we successfully plan, implement and manage waste management biogas projects both nationally and internationally. All our products are put through their paces in our own [Test]facility at our site in Bernau am Chiemsee. Thanks to their durable design, our machines can be used in a wide range of applications. At Finsterwalder Pumptechnik, for example, the areas of use and applications go beyond biogas technology.

The diversity of fermentable waste

Raw materials

Raw materials

OUR PRODUCTS CAN BE USED IN A VARIETY OF WAYS

OUR PRODUCTS CAN BE USED IN A VARIETY OF WAYS

Our components are designed for processing biological waste and food waste, as well as agricultural residues with their different requirements. The residual materials listed here are examples and are not exhaustive. We will find the solution for your applications!

Municipal waste

and residual materials e.g.

- Organic waste, brown garbage can

- Green cuttings and garden waste

- Household waste

- Sewage sludge...

Industrial waste

and residues from food and animal feed production e.g.

- Milk processing

- Beverage production

- Pharmaceutical industry

- Fruit residues and pulp...

Gastronomy

Food waste from commercial kitchens such as canteens, hospitals,...

Wholesale markets

- Fruit and vegetable scraps (including citrus fruit)

- Discarded or unsold goods

- Food with an expired use-by date

- Complete wheel rims (transport damage, interrupted cold chain, etc.)

Waste from animal husbandry

- Cattle manure, pig manure, poultry manure, dry chicken manure

- Solid manure

Vegetable waste

- Unsaleable or spoiled fruit or fruit parts

- Feed residues, mashed grain

- Catch crops

Organic waste

Packed and unpacked

Leftovers

Solutions for large-scale catering

Agriculture

Residual materials and production waste

Everything from a single source

Complete system

Complete system

Developed & tested for over 25 years

Developed & tested for over 25 years

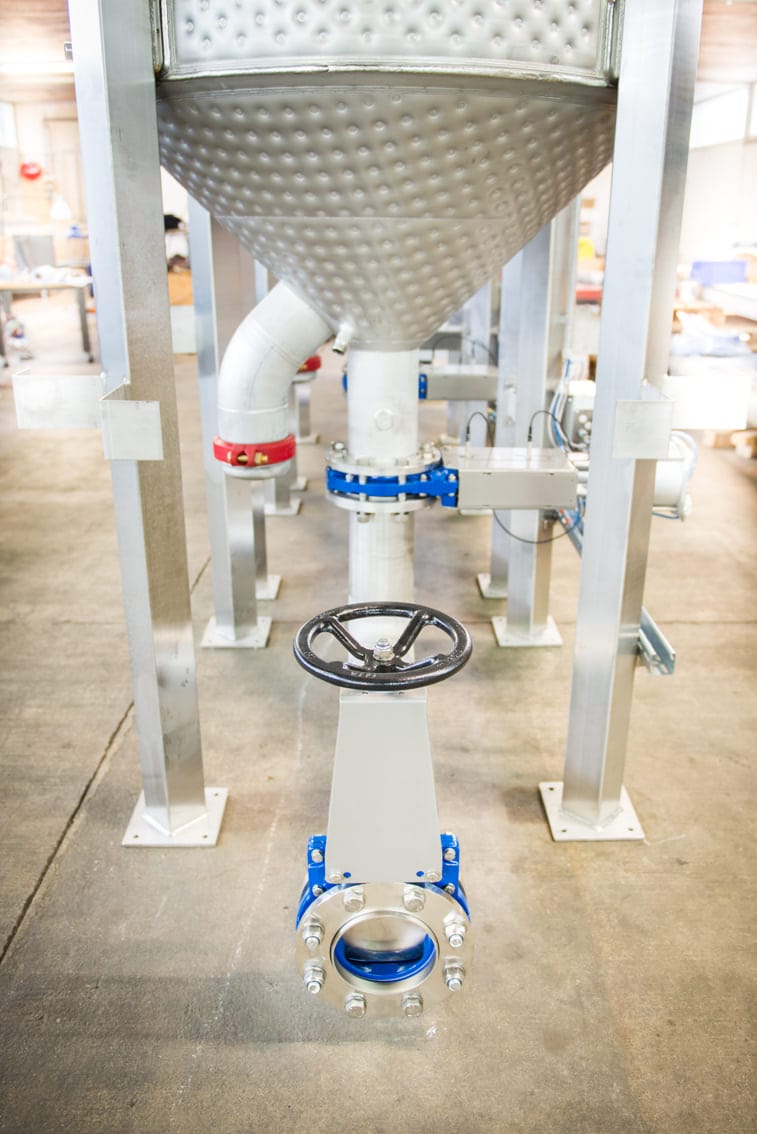

All components and systems are developed for long-term and reliable operation. In our own plant, we gather the experience that supports our mechanical engineering during development. Our FINSTERWALDER system is the basis for an economical process.

Everything from a single source

Sub-processes

Sub-processes

Reliable technology for all process areas

Reliable technology for all process areas

From separating fermentable and non-fermentable waste components to automatic process control of the biology in the Digester, we offer the right solutions for all areas of the biogas production process. The modernization of existing plants is one of our strengths. We find solutions for your individual applications!

Problem definition

Removal of contaminants from digesters

Solution

Continuous discharge of sinking and floating contaminants as well as floating sludge discharge during operation

Finsterwalder machines

Floor scraper

Skimmer (side or top mounting)

Problem definition

Local fermentation of food waste from large-scale gastronomy.

Solution

Container concept with integrated FINSTERWALDER technology

Finsterwalder machines

- An intake hopper that can be opened and closed hydraulically

- Inline shredder for the fiber components (straw)

- KP10 Feed pump

- Separation for stones etc.

Problem definition

Transfer and circulation of the fermentation product from the Digester to the composting process.

Solution

Two Finsterwalder KS23 gate valve pumps are filled alternately via a Y-piece, both pumps are operated simultaneously, continuous transfer of the fermentation product to the composting system.

Finsterwalder machines

Gate valve pump KS23

Hydraulic power unit

Control cabinet and automation

Sewage treatment plants

Discharge of foreign matter in the digestion tower

Small biogas plant

Local for e.g. large-scale gastronomy

Composting plant

Transfer of materials

PHOTO STORIES AND REPORTS OF SUCCESSFUL PROJECTS

Case Studies

Case Studies

Successful projects

Successful projects

Numerous reference projects demonstrate the high performance and versatile applications of the FINSTERWALDER process and components.

Case Studies

Biowaste treatment Asdokshof – Pumptechnology

Charging material:

- unknown

Case Studies

Biogas plant URUMQI (CN) – Planning biogas plant

Charging material:

• 300 t/day of kitchen wast

Case Studies

Rothmühle AES GmbH (DE) – Planning of wet fermentation plant

Charging material:

• 32,000 t/a

• Municipal organic waste and food waste

Case Studies

EcoCenter Lana (IT) – Revision of hydrolysis

Charging material:

• 32,000 t/a

• Municipal organic waste and food waste

Case Studies

Composting plant Anröchte – Pumping technology

Charging material:

- unknown