Project details

Project:

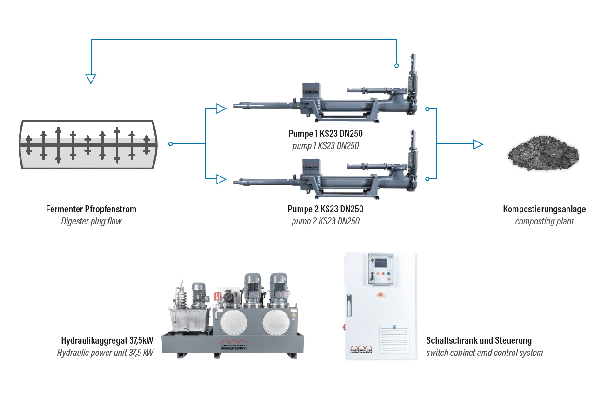

Composting plant Anröchte – Pumping technology

Process area:

Case Studies

Charging material:

unknown

Brief description of the project

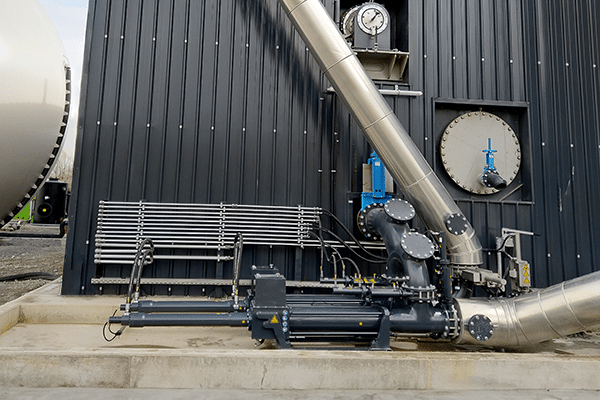

Entsorgungswirtschaft Soest GmbH collects and recycles approx. 30,000 t/a of organic waste at the Anröchte composting plant. The existing composting plant was expanded in 2020 to include fermentation. The tender was won by Hitachi Zosen INOVA AG for the fermentation part. Finsterwalder Umwelttechnik in turn was allowed to supply and install the pump technology for circulation and transfer of the fermentation product from the fermenter to the composting system. The pump capacity is adjustable between 12 and 22m³/h at 10bar delivery pressure.

Integrated FINSTERWALDER technology

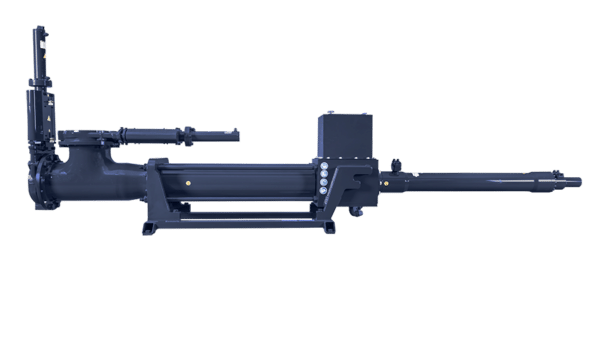

- 2x gate valve pump KS23 – DN250

- 1 x hydraulic unit 2 x 15kW

- 1 x control unit

Services

- Delivery

- Construction

- Assembly

- Commissioning

- Maintenance

Waste treatment processes

Procedure in detail

One pump pushes the fermentation product back into the fermenter via a DN250 pipe. Both pumps

are operated simultaneously to continuously transfer the fermentation product into the compost mixer.

other valves on the system. It has a 600L oil tank, a WHG oil pan and consists

of three oil circuits.

and remote access. In addition, the fermentation product should be sent to the

compost mixer as continuously as possible. For this purpose, frequency inverters were installed, which allow both pumps to be operated

in a coordinated manner.

Similar projects

Our technology offers individual solutions for all process areas in the field of biogas and anaerobic digestion of organic waste. We support our customers from the initial idea through to planning, implementation, commissioning and ongoing operation. Similar projects of our worldwide customers can be found here!

Biology, Case Studies, Digestion, Pasteurization, Pre-Treatment, Pumps

Biopower Bernau (DE) – The own biogas plant, test plant

Charging material:

• 6,000 t/a

• Commercial food waste

• Municipal waste

Digestion, Pasteurization, Pre-Treatment, Pumps

Langage Farm AD (UK) – Equipment for substrate cleaning

Charging material:

• 18,000 t/a

• Kitchen waste from the catering trade

Biology, Digestion, Pre-Treatment

Jiangjin (CN) – Treatment plant and fermentation

Charging material:

• 75,000 t/a

• Contaminated kitchen waste