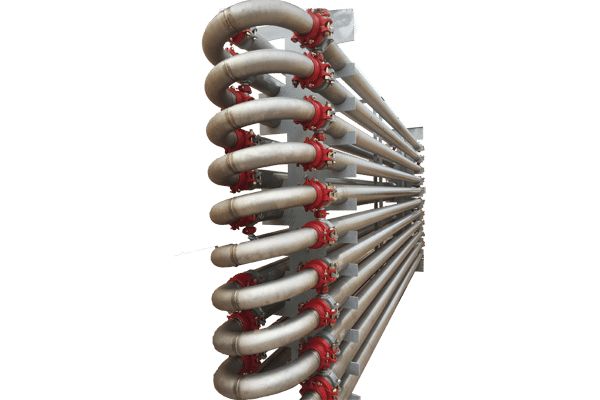

Customer-specific solutions for tempering and hygienizingfermentation substrates

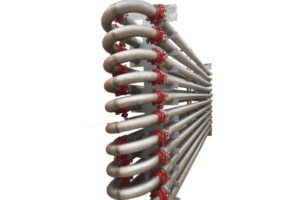

We manufacture and install type WT10 double-tube heat exchangers in various lengths of up to 400 meters, depending on the throughput capacity and desired final temperature!

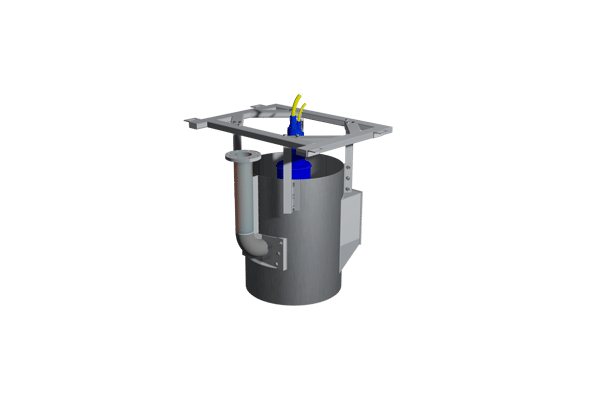

Typical applications Double-tube heat exchangers

- As external digester heating

- For heating material that must be pasteurized to > 70 °C

- As a cooling section after pasteurization

Technical data

- All parts in contact with the medium are designed to be corrosion-resistant

- Pipe inside diameter of the product line DN100 (standard); for special applications up to DN200!

- Pressure stage: PN40

- Flow temperature according to customer requirements

- Modular design in 6 m segments, thus flexibly adaptable to the spatial conditions

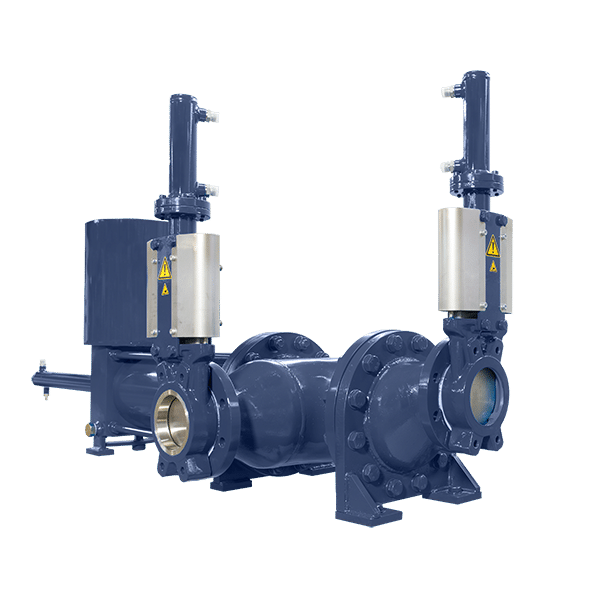

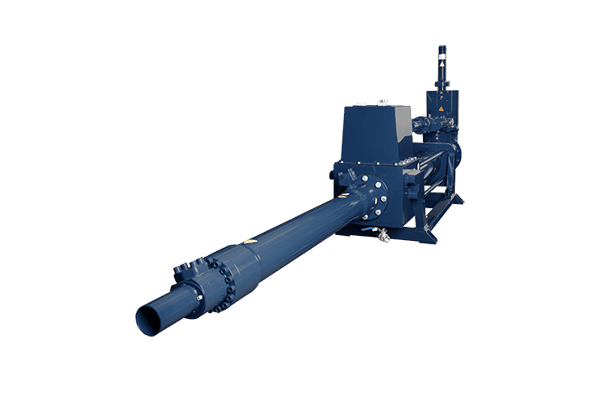

Similar products

Individual requirements also call for specific solutions. Our product range offers applications for a wide variety of process areas and can be adapted to your requirements. Find out more about the products we have developed and tested in our own plant.