Manual bicarbonate monitoring

Long-term proven process control for biogas plants – The importance of the bicarbonate parameter

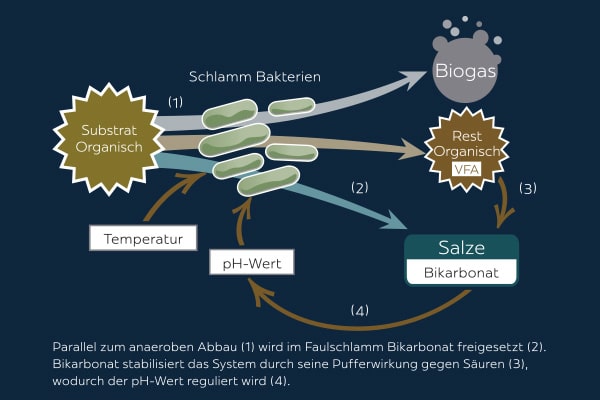

For efficient biogas production, digested sludge bacteria require a pH value in the range of around 6.5 to 8. Stabilization of the pH value in this range is mainly achieved (> 85 %) by the bicarbonate (= buffer substance) released in large quantities during anaerobic decomposition. Process disturbances regularly lead to increased concentrations of free fatty acids (FFA) or to decreasing bicarbonate contents, as the acids consume bicarbonate. However, the buffering effect of the bicarbonate means that the pH value is hardly reduced at first. Only if the disturbance lasts for a long time and the supply of bicarbonate is largely exhausted does a rapid drop in the pH value occur and subsequently a reduction or, in extreme cases, a failure of biogas production.

Advantages of process control with the bicarbonate tester

- With the bicarbonate tester, process faults are detected earlier, in contrast to an exclusive pH value check – there is more time to avoid economic losses

- Very simple operation

- Results after just 5 minutes!

- Data is easy to interpret

- Measurement technology does not require calibration

- Very low consumption costs

- Robust, long-term proven measurement technology

Interested in fully automatic bicarbonate monitoring?

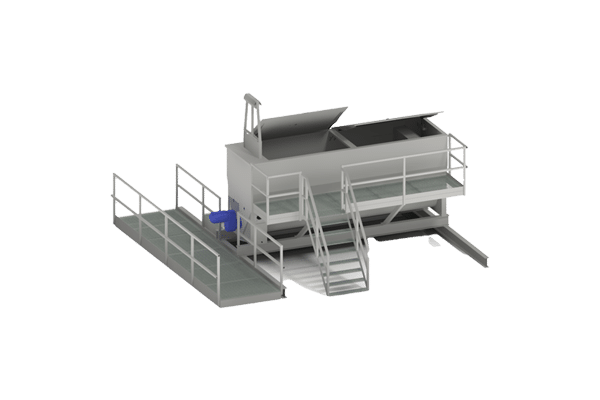

Automatic bicarbonate monitoring with the bicarbonate analyzer

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationSimilar products

Individual requirements also call for specific solutions. Our product range offers applications for a wide variety of process areas and can be adapted to your requirements. Find out more about the products we have developed and tested in our own plant.